The clutch is arguably the most critical component connecting a driver’s intent to mechanical action. Far from being a simple engagement plate, the system allows for the controlled transfer of engine torque to the transmission, facilitating seamless gear changes and efficient power management.

For any automotive enthusiast or engineer, gaining a deep understanding of the diverse automotive clutch types is fundamental to appreciating how power is managed across everything from entry-level commuter cars to multi-million dollar hypercars.

This guide explores the engineering, application, and cultural significance of various clutch mechanisms that define the modern driving experience.

The Pillars of Power Transfer: Foundational Clutch Types

The vast majority of vehicles rely on three core clutch types, each dominating a specific market segment based on torque capacity and operational need.

1. The Friction Clutch (Single-Plate & Dry)

The single-plate, or dry friction, clutch remains the undisputed king of manual transmission vehicles. Its design is elegantly simple and highly effective:

- Mechanism: It consists of a single clutch disc coated in high-friction material, pressed firmly against the engine’s flywheel by a spring-loaded pressure plate.

- Function: When the driver depresses the clutch pedal, a release bearing (or thrust bearing) acts on the pressure plate, momentarily decoupling the engine from the gearbox input shaft, allowing for a gear change.

- Application: Its low cost, excellent efficiency, and simplicity make it standard equipment on almost all non-performance manual cars and light trucks.

2. The Multi-Plate Clutch (Wet & High-Performance)

When high torque and continuous cooling are necessary, the multi-plate design takes precedence.

- Mechanism: This system stacks several smaller friction plates and steel separator plates, all contained within a compact housing.

- Advantage: By increasing the total frictional surface area without increasing the overall diameter, the clutch can handle significantly higher torque loads with less slip.

- Application: Essential for high-performance cars (like those in F1 or World Rally Championship), motorcycles, and increasingly common in modern wet dual-clutch systems (DCT) where oil lubrication is used to cool the plates.

3. The Centrifugal Clutch (Automatic Engagement)

This clever clutch mechanism eliminates the pedal entirely, making it ideal for simplicity.

- Mechanism: Weighted arms within the clutch housing swing outward as engine RPM increases (centrifugal force). At a predetermined speed, these weights overcome the spring tension and press the friction shoes against the drum, engaging the drive.

- Application: Primarily found in mopeds, go-karts, lawnmowers, and older snowmobiles where the simplicity of a self-engaging, automated system is prized over manual control.

Clutch Types in Modern Automotive Engineering: The Digital Age

The 21st century has brought about revolutionary advancements in power management, with automation and electronic control enhancing performance and convenience.

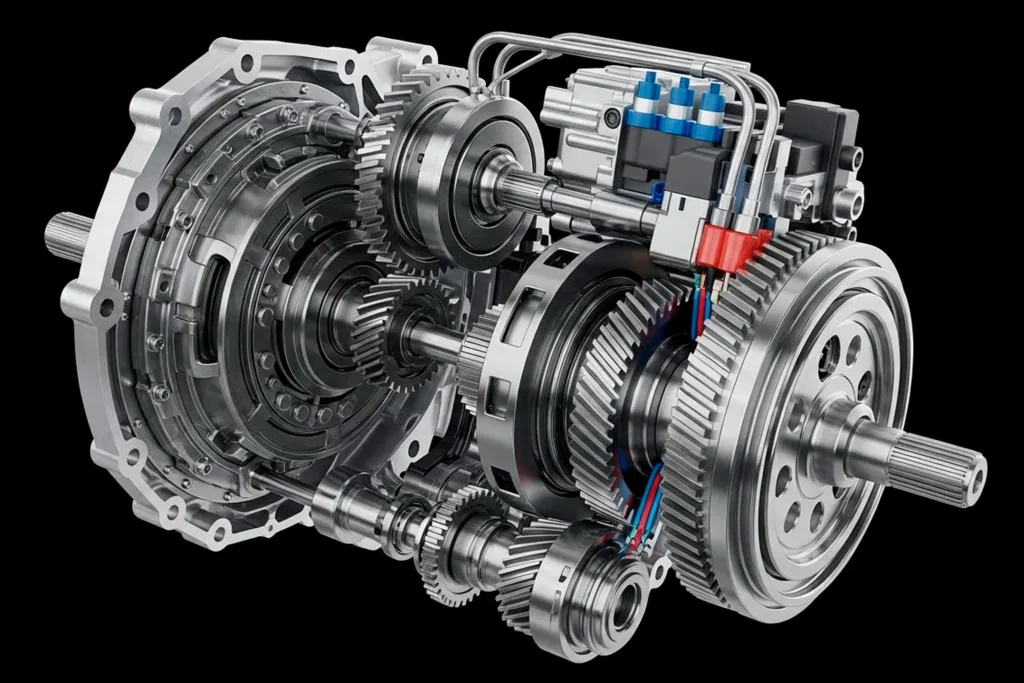

The Dual-Clutch Transmission (DCT)

Perhaps the most significant innovation in recent decades, the DCT utilizes two separate clutch mechanisms to achieve lightning-fast, seamless shifts.

- How it Works: One clutch manages the odd gears (1, 3, 5, 7), while the other manages the even gears (2, 4, 6, R). While the car is in 1st gear, the second clutch pre-engages 2nd gear. When the shift command is given, one clutch instantly disengages while the other simultaneously engages—resulting in no discernible break in torque delivery.

- Impact: This technology effectively marries the fuel efficiency of a manual gearbox with the convenience and speed of an automatic, transforming the performance landscape in everything from hot hatchbacks to luxury supercars. This evolution proves that even fundamental clutch types can be reimagined for modern demands.

Hydraulic and Electro-Mechanical Actuation

While the type of clutch (e.g., single-plate) determines the torque capacity, the method of actuation determines the feel and control.

- Hydraulic Clutch: Uses fluid pressure to transfer force from the clutch pedal to the pressure plate, offering a smoother, more consistent pedal feel than older cable-actuated systems.

- Electromagnetic Clutch: Utilizes an electrical current to generate a magnetic field, which engages the clutch plate. This allows for precise, instantaneous electronic control, often found in specialized applications like air conditioning compressors or certain automated manual transmissions (AMTs).

Niche and Performance Clutch Mechanisms in Car Culture

Beyond the mainstream, several specialized clutch types continue to play vital roles in specific areas of the car culture world:

- Cone Clutch: A progressive engagement clutch where friction surfaces are conical. Its wedging action provides high torque capacity in a small space, making it frequently used in the synchronizer rings of manual transmissions to match gear speeds before engagement.

- Wet vs. Dry Clutches: This distinction relates to lubrication. Dry clutches (like the standard single-plate) operate without fluid, maximizing efficiency but requiring larger size for high torque. Wet clutches (common in DCTs and motorcycles) are bathed in oil for cooling and component longevity, allowing for a much smaller multi-plate design to handle high heat and power.

- Dog Clutch (Positive Contact Clutch): A non-slip mechanism that uses interlocking teeth (or ‘dogs’) instead of friction. Engagement must occur when both shafts are rotating at or near the same speed. It is used in heavy-duty transmissions and motorsports where the absolute lack of slip is required, despite offering a less refined shift than friction-based systems.

Clutch Types and the Pursuit of Performance

The clutch assembly is a frequent target for modification in the tuning and motorsport communities. Changing the clutch type or its components is one of the most effective ways to upgrade a car’s performance envelope, especially after significant engine tuning.

- Tuning Upgrades: Enthusiasts often upgrade to high-performance friction materials (like ceramic or organic compounds) or convert to multi-plate systems to cope with boosted engine outputs. A stronger clutch is essential for maximizing a car’s launch capability and reducing power loss through slip.

- Driving Experience: The choice of clutch dictates the tactile experience of driving. A heavy-duty racing clutch mechanism may offer superior grip but require immense pedal effort, while a factory-spec hydraulic clutch prioritizes comfort and everyday usability. This choice between comfort and performance lies at the heart of much of car culture modification.

The humble clutch is a true marvel of mechanical ingenuity.

From the simplicity of the friction disc to the hyper-complex, dual-computerized system of a DCT, the various automotive clutch types showcase the diverse ways engineers have solved the fundamental problem of connecting and disconnecting power.

Understanding these different clutch mechanisms provides an enriched appreciation for the mechanical heart of every vehicle.

Functional Always active

Preferences

Statistics

Marketing